Best Mining Boots | Expert Guide to the Best Boots for Miners

Posted by Cara Spindler on Nov 20th 2023

Best Mining Boots | Expert Guide to the Best Boots for Miners

Best Mining Boots

by CARA SPINDLER

Mining Operations have expanded in recent years and heading into 2024 there is going to be a very high demand for Miners, and hence the need for the best made protective Mining Boots the work boot industry can provide.

The Mining Industry is the supplier of extracted natural solid minerals to the world, such as; coal, metals, industrial minerals, sand and gravel.

Just how extensive is the Mining Industry in the U.S. today?

Mineralsmakelife.org, explains that American industries "...transform these minerals into the infrastructure and products we use every day" and have "...added more than $3.02 trillion to the U.S. economy, which is more than 14 percent of the GDP."

Mining today in the United States is widely done, either through Open Surface (Pit) Mining, or Underground Mining, but it is also done, to a lesser extent, with other methods; such as Placer Mining and In-Situ Mining.

Over 95% of all active mining operations in the USA today are done utilizing surface mines, with the remainder being more expensive, deep mining operations that are situated far below the ground, or through other types of methods.

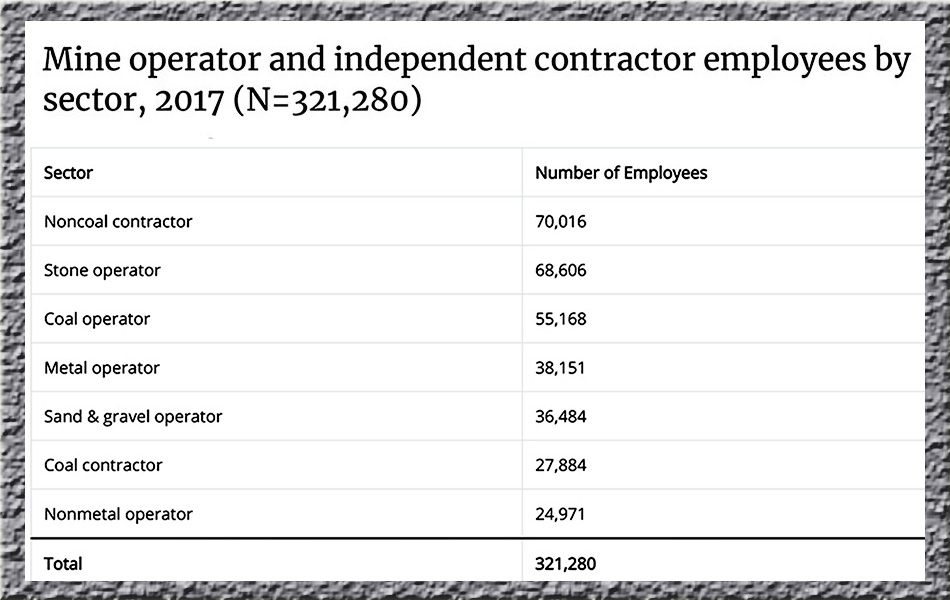

According to the National Institute for Occupational Safety and Health (NIOSH), in 2017 there were well over 300,000 employees working within the Mining Industry, all in varying capacities.

Statistics courtesy of NIOSH*

Four Basic Types of Mining Methods

- Open Pit (Surface) Mining

Open Pit Mining is sometimes referred to as Strip Mining, and 2/3 of all the Coal Production in the United States is from this type of mine. Surface Mines are routinely used to get at valuable Coal or Ore, (such as Uranium Ore) that sits less than 200' below the ground. First, the topsoil layer is removed and then the Overburden is removed, which is the layers of rock that lie just beneath the topsoil. Once the ore, or coal streams, are exposed, the materials can be extracted.

- Underground (Deep) Mining

Underground Mining is done in order to reach much deeper deposits, that are sometimes thousands of feet below the surface. Large machines are brought down into these mines to mechanically dig out the coal. These deep mines have series of tunnels that branch out, sometimes extending for miles. Miners will travel down on elevators and then ride small trains through the deep tunnels to get to a current dig site. After extraction, the Coal is transported out of the mine via conveyors, mine carts, or trams.When the coal reaches the surface, trucks are used to move the product to further locations. Underground mining is also used for harvesting Uranium, which is drilled,and then blasted, to create piles of debris.This debris is transported to the surface, where it will be sent on to a mill for processing.

- Placer Mining

Placer Mining is used as a method of sifting out valuable metals that are hidden within the sediment of riverbeds, beach sands, or other environmental terrains by washing, dredging, or using hydraulics. Hydraulic Mining uses high-pressure jets of water to dislodge rock material or to to blast away sediment. This creates a slurry that is run through sluice boxes in order to filter out the precious metals, such as gold.

- In-Situ Recover (ISR) Mining

In-Situ Mining is the preferred method of extracting Uranium. In this type of mine, water is mixed with a solution and then forced down into the mine via a well, so it can flush the Uranium out right at the source. The well's pump then forces the now water-enriched Uranium directly up to the surface. Once above-ground, that enriched water is treated and filtered to fully release and isolate the Uranium.

Supportive Mining Jobs

Workers within the Mining Sector include not only those who perform the actual extraction of minerals, such as coal and ore, but it also includes those workers who initiate or further that process.

Some of the other jobs involved with mining would be:

- Mine Official

- Mine Prospector

- Mining Engineer

- Emergency Structure Engineer

- Timber

- Hewer (Breaker, Pickman)

- Driller

- Loader

- Breaksman

- Putter

- Barrowman

- Hurrier

Supportive mining jobs would also include well operators and those involved with the physical process of Milling, which is the process of working to crush, pulverize, screen and wash the extracted minerals. These supportive jobs would include Heavy Machine Operators, as well as the truckers who transport these minerals from one location to another.

Safety: The Number One Concern in Mining

Mining: One of the Most Dangerous Jobs in the World

Mining is so dangerous, because there are serious physical risks involved in this line of work.

Therefore, when it comes to the Mining Industry safety is their number one priority for all of its workers, not just the ones who are physically extracting the materials. Safety is a main concern for those involved in setting up the initial staging areas for the mining operations, as well as for those involved in the later stages of processing once these materials have been extracted.

Whether working above-ground, or hundreds of feet below-ground, if you work in the coal mining, mineral mining, or the precious metal mining industry, safety begins with your safety gear, from head to toe, starting with your helmet, then down to your safety vest and gloves, and right on down to your boots.

Especially your boots.

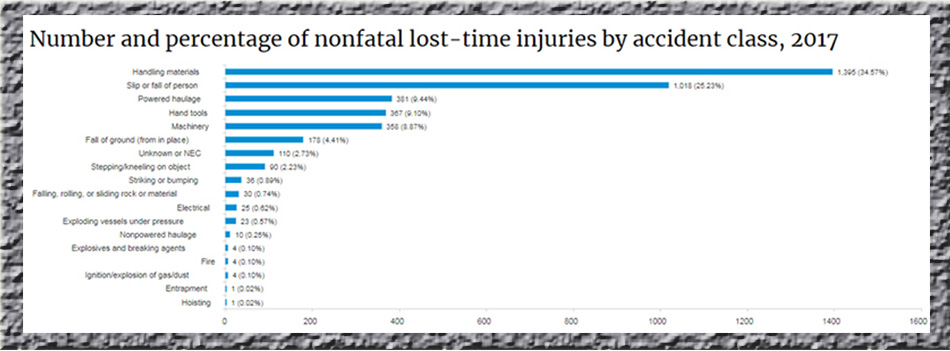

Statistics courtesy of NIOSH*

According to the NIOSH, in 2017 Slip or Falls accounted for 25.23% of all non-fatal lost-time injuries by accident within the Mining Industry.

NIOSH also documented that 2.23% of all injuries were the result of Stepping or Kneeling injuries, and 89% were from Bumping and Striking injuries.

What You Wear on Your Feet Matters

Whether you are a miner, a mining engineer, a mine official or a prospector, proper foot protection is key for protection on the job. Mining Boots need to be tough and rugged, and they should be abrasion-resistant from top to bottom.

Many Mining Boots Incorporate Kevlar Into Their Boot Shafts.

Kevlar is a synthetic fiber made only by DuPont USA and its properties are so strong that it was first used in the 1970's to replace steel in racing tires.

Kevlar is a high-strength fabric that is widely used across Law Enforcement's Tactical Boots and their Bullet-Proof Vests, because it is extremely resistant to rips and tears and can even stop a bullet.

Deep Mining Boots Have a Shortened Life-Span

Bear in mind, that if your mining job requires you to work far below the surface, additional pressures will be placed on your work boots on a daily basis.

Most deep mining boots will only last 2-3 months, because the conditions down below are so much more extreme. This is why investing in a highly protective pair of mining boots is crucial for protecting your feet, as well as your legs.

What Are the Best Boots to Wear for Mining?

Look for solid protective features, with high levels of ankle support, to prevent ankle rolls. You should also wear boots that do not feel heavy and clunky, or feel as if you are dragging your feet when you wear them. A good pair of Mining Boots will fit well and allow you to walk naturally, while preventing against accidental bangs, slips or falls.

Mining Boots Should Have These Safety Features:

- Traction Outsole

- Waterproof Membrane

- Safety Toe

- Metatarsal Protection

- Puncture Resistant Outsole

- Thinsulate Insulation

- Sufficient Boot Height

- Torsion Control

-

Traction Outsole

Mining Boots must provide miners with a solid platform and excellent traction. If you work at a Placer or Open Pit Mining site, the terrain can vary from rough and rocky, to dry and loose sandy soil, and some days to wet muddy ground.

When working in Open Pit Mines, it is not uncommon to be climbing machinery, or equipment, via conveyor belts, or grated metal walkways, that can very easily become treacherous.When working far underground performing Deep Mining work, the tunnels can be dark, with vision being difficult for seeing ground that is uneven, rocky or pebbly. Sometimes tunnels will become waterlogged, and will result in muddy minecart rails becoming slick and slippery.

Miners need to keep footing secure while walking across the jobsite, such as when walking on inclined ramps and grates, traversing walkways, crossing minecart rails, going up or down metal stairways, or while climbing on and off various types of machinery.

Therefore, Mining Boots must have outsoles with deep, multi-directional lugs that can channel water underfoot, and provide serious dig-in traction on earth-packed inclines and that will allow for quick pivots under any dry, wet, or muddy conditions. -

Waterproof Membrane

Underground tunnels can become water-logged, so wearing rubber boots is essential.

However, if the outside of the boots is not of a good quality thick rubber, they can easily be cut, torn, or worn through, allowing water to penetrate into the boots and around your feet. If this happens, it is not just uncomfortable, it can create dangerous foot slippage within the boots. This slippage can compromise your ability to keep secure footing, it can also compromise good foot health, as bacteria will breed in moist, warm environments like rubber boots..

You need mining boots that have an an impenetrable waterproof membrane.

While a thick rubber exterior is always your first line of defense in keeping feet dry, you should have an interior layer that works to seal out water 100%. This way if the outer rubber shell gets cut, torn or punctured, the waterproof membrane will be your second line of defense against preventing water from seeping into the boots.Modern waterproof membranes are scientifically engineered with a dual purpose; to seal out water and to keep boots breathable.

The science behind this is actually quite simple.

The membrane is weaved with tiny holes that allow tiny air molecules the ability to pass through into the boots, creating good airflow. This helps assure feet will not get overheated, and allows for sweat to evaporate off of the feet, preventing bacteria build-up.However, water cannot get in through these tiny holes, because water molecules are much larger than air molecules. Water simply cannot penetrate through the fabric.

-

Safety Toes

Mining Boots should have solid toe protection, especially when working on the surface, working around bulldozers, back loaders and dump trucks, and underground when working around foot-crushing equipment such as underground minecarts and excavators (diggers.)

Traditional Steel Toe Boots Have Always Been a Favorite of Miners

However, the newer technologies used in Composite Toe boots are extremely popular because they are every bit as protective as steel, but have some advantages. Composite materials are much lighter in weight than steel, plus they will not conduct heat or cold into the toe box area of the boots. -

Metatarsal Protection (Met Guards)

The bones on the top of the feet are called the Metatarsals. All good mining boots will have Internal Metatarsal Guards, that help prevent injuries to the delicate bones on the top of the feet.

The Metatarsal Bones need extra protection in a hazardous mining environment, from tools and equipment that might drop onto, or roll over on top of the feet, and to guard against the accidental banging of the top of your feet against equipment in cramped, dark or low-lit areas.

-

Puncture Resistance

Puncture Resistant Outsoles prevent sharp hazards that may be underfoot from penetrating up through the outsoles and into the bottom of the feet. This is especially important when working in an underground mine shaft that is dark and dimly lit, or when working in a waterlogged mine tunnel, with unseen dangers that may be lurking beneath the water. -

Thinsulate Insulation

Mining Boots should have some level of insulation, whether working outdoors in the elements, or when working a thousand feet underground in a mineshaft.

Thinsulate insulation is designed to be a very thin layer built into the wall of the boots that goes virtually unnoticed. It traps your body's heat within the toe box area of the boots, so when you are working in cold, or damp and chilly conditions, your feet will stay warm and comfortable. -

Boot Height

Mining Boots come in a variety of heights, from 10” all the way up to 16”. Mining boots are designed to be tall, so they can provide extra support and protection to your ankles, shins and calves. The Mining Boots' height should guard against painful bangs into job equipment or machinery in poorly lit tunnels

-

Torsion Control

It is important to wear mining boots that offer good torsion control. Torsional structure gives feet lateral rigidity when walking on uneven terrain on a jobsite. Torsion Control will discourage the accidental rolling of the ankles as well as prevent the bending and twisting of the midfoot area.

The Best Boots for Mining

When it comes to choosing the best boots to invest in, when working in the Mining Industry, keep in mind the features discussed. Search out a reputable work boot brand that makes boots specifically for mining. One that understands the serious nature of the job, that offers mining boots that are both protective and durable.

Expert Picks for the Best Mining Boot Brands

-

Matterhorn Mining Boots

Matterhorn is a leader in the industry and offers a wide selection of Mining Boots for both men and women.

-

LaCrosse Mining Boots

LaCrosse extends its quality-made footwear into the Mining Industry, with a full line of protective Mining Boots.

-

Timberland Gravel Pit Mining Boots

Timberland makes a best-selling Mining Boot called the Gravel Pit, which is popular and in very high-demand.

Other Premium Work Boot Brands at Family Footwear Center

- Chippewa Boots

- Danner Boots

- Carolina Boots

- Timberland PRO Boots

- Rocky Boots

- Georgia Boots

- Wolverine Boots

- Keen Utility

- Iron Age Boots

Refenced Sources:

* https://mineralsmakelife.org/

** https://wwwn.cdc.gov/niosh-mining/MMWC/Injuries/Count

This blog article was updated on 11-20-2023 to ensure latest expert information.

***********************************************************************************************************

Real Made in the USA Work Boots

Elusive as a Yeti

by CARA SPINDLER

Expert advice on buying

REAL Made in the USA Work Boots

***********************************************************************************************************

7 Best Landscaping and

Landscape Construction Boots

by CARA SPINDLER

Expert Advice on the best Landscape and Landscape Construction Boots

based on safety and performance

***********************************************************************************************************

6 Best Lineman Boots | Expert Guide to the Best Pole Climbing Boots

by CARA SPINDLER

Expert Advice on the Best Boots For Linesmen

for Tower Climbing & Pole Climbing